Research Area: Area Selective Atomic Layer Deposition

Nanostructured materials are widely employed in various applications, from electronic devices and catalysis to batteries and solar energy. Modern fabrication schemes typically rely on a series of 'top-down' steps in which bulk materials are broken down into desired nanostructures. In contrast to top-down methods, bottom-up approaches assemble basic units into larger desired nanostructures. They are considered a promising strategy due to their ability to create nanostructures with fewer defects and better precision. Area selective deposition is a method that allows direct deposition of materials only on desired areas that has attracted great interest due to its bottom-up nature. Our group studies various approaches to area selective atomic layer deposition.

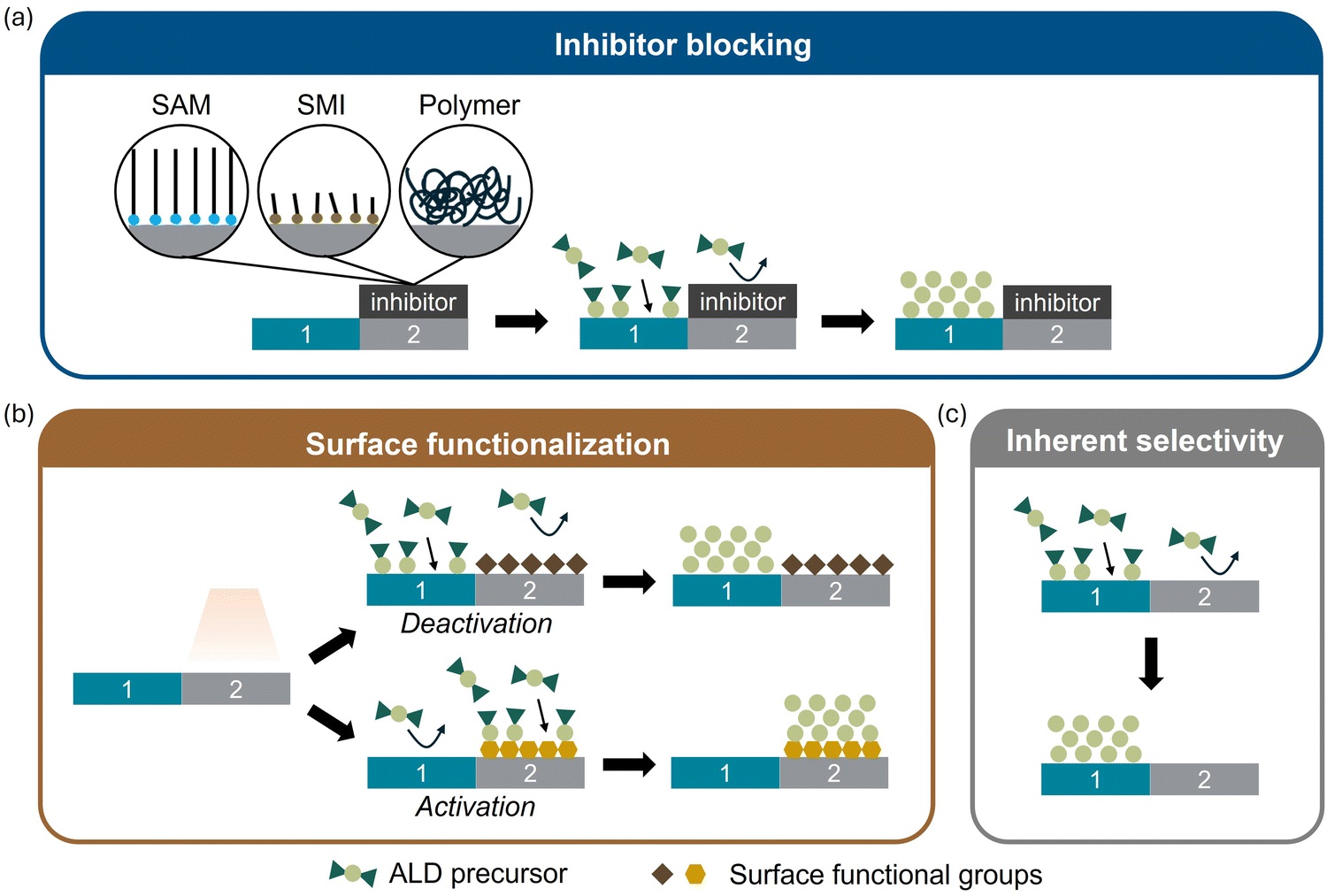

Above: Schematic of different approaches to achieve selective deposition on one surface (surface 1) over the other (surface 2) or vice versa: (a) inhibitor blocking, with inhibitors such as self-assembled monolayers (SAMs), small molecule inhibitors (SMIs) and polymers, (b) surface functionalization (of surface 2), and (c) inherent selectivity. Liu, T.-L.; F. Bent, S. Materials Horizons 2025. https://doi.org/10.1039/D4MH01472C

Whereas ALD inherently provides nanoscale control of materials in the vertical direction, area selective ALD enables nanoscale definition of the lateral structure. In area selective ALD, we attach inhibitory molecules such as self-assembled monolayers, polymers, and small molecule inhibitors to regions of the substrate to prevent ALD. We can achieve area selective ALD of a range of deposited materials onto dielectric/dielectric, metal/dielectric, carbon/dielectric, and multicolor patterns. By tuning this pre-growth step, in addition to optimizing the ALD process that follows, we can facilitate the selective growth of materials in desired growth areas.

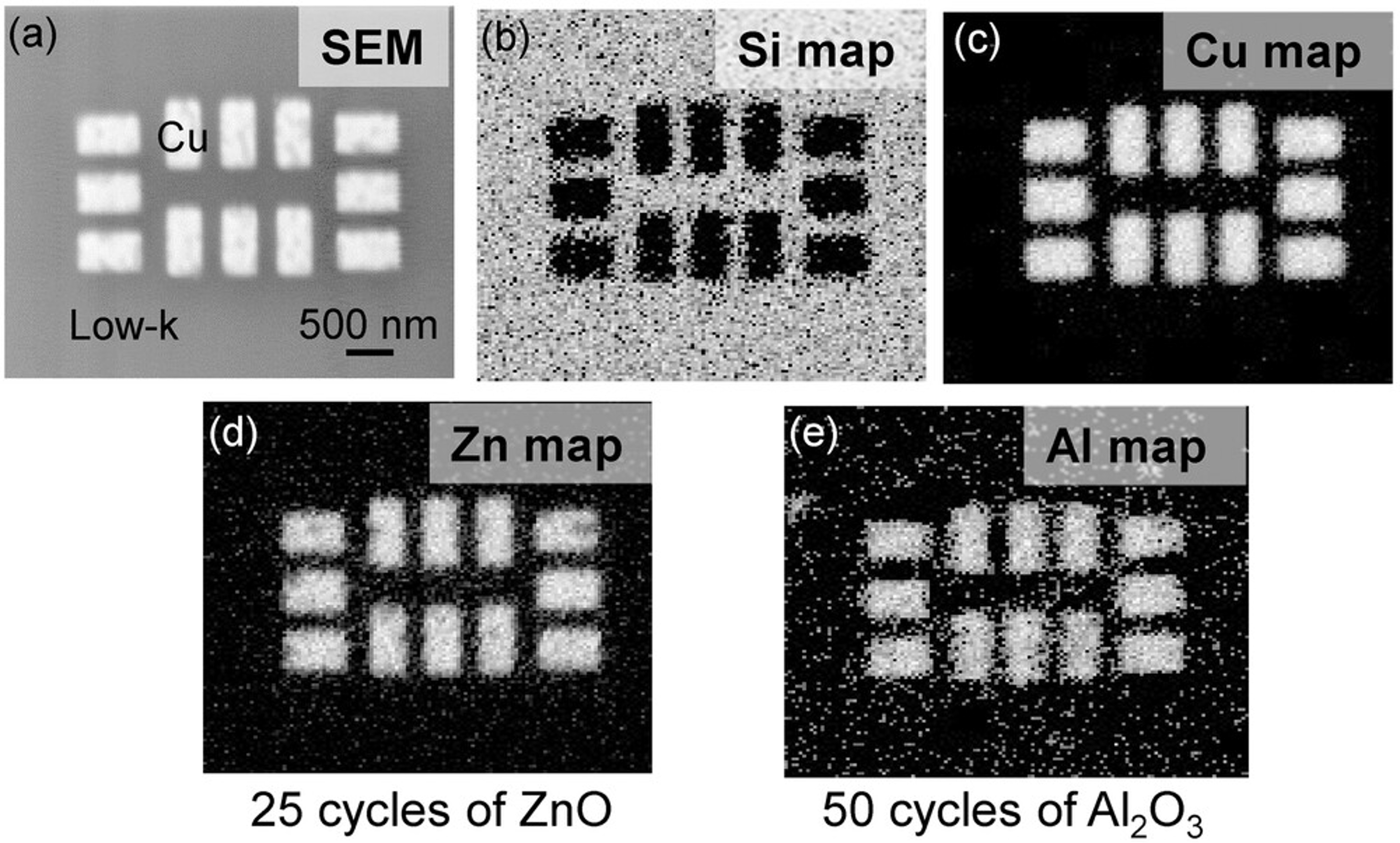

Above: (a) SEM image; (b) Si and (c) Cu elemental mappings determined by AES of a Cu/SiCOH low-k dielectric pattern. (d) Zn and (e) Al elemental mappings from AES of Cu/SiCOH low-k dielectric patterns treated by DDT followed by OTMS after ZnO and Al2O3 ALD, respectively. All images are at the same scale.

Liu, T.-L.; Harake, M.; Bent, S. F. Advanced Materials Interfaces 2023, 10 (5), 2202134. https://doi.org/10.1002/admi.202202134

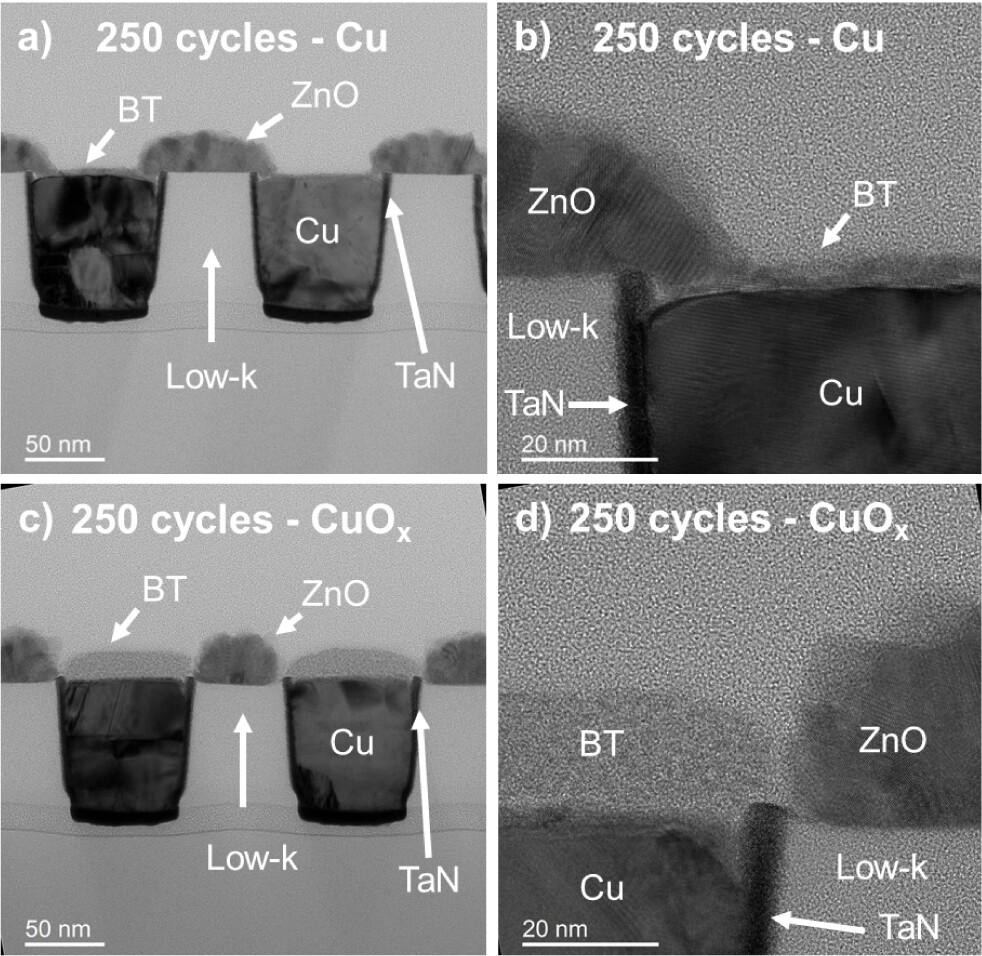

Above: Cross-sectional TEM of 250 cycles of ZnO ALD on BT-treated (a, b) Cu/SiO2 and (c, d) CuOx/SiO2 samples, respectively. The images on the right are zoomed-in versions of those on the left.

Shearer, A.; Cho, Y.; Kim, M.; Werbrouck, A.; Liu, T.-L.; Takacs, C. J.; Shong, B.; Bent, S. F. ACS Nano 2025, 19 (12), 11936-11948. https://doi.org/10.1021/acsnano.4c16115