Research Area: Organic-based Nanoscale Thin Films (MLD)

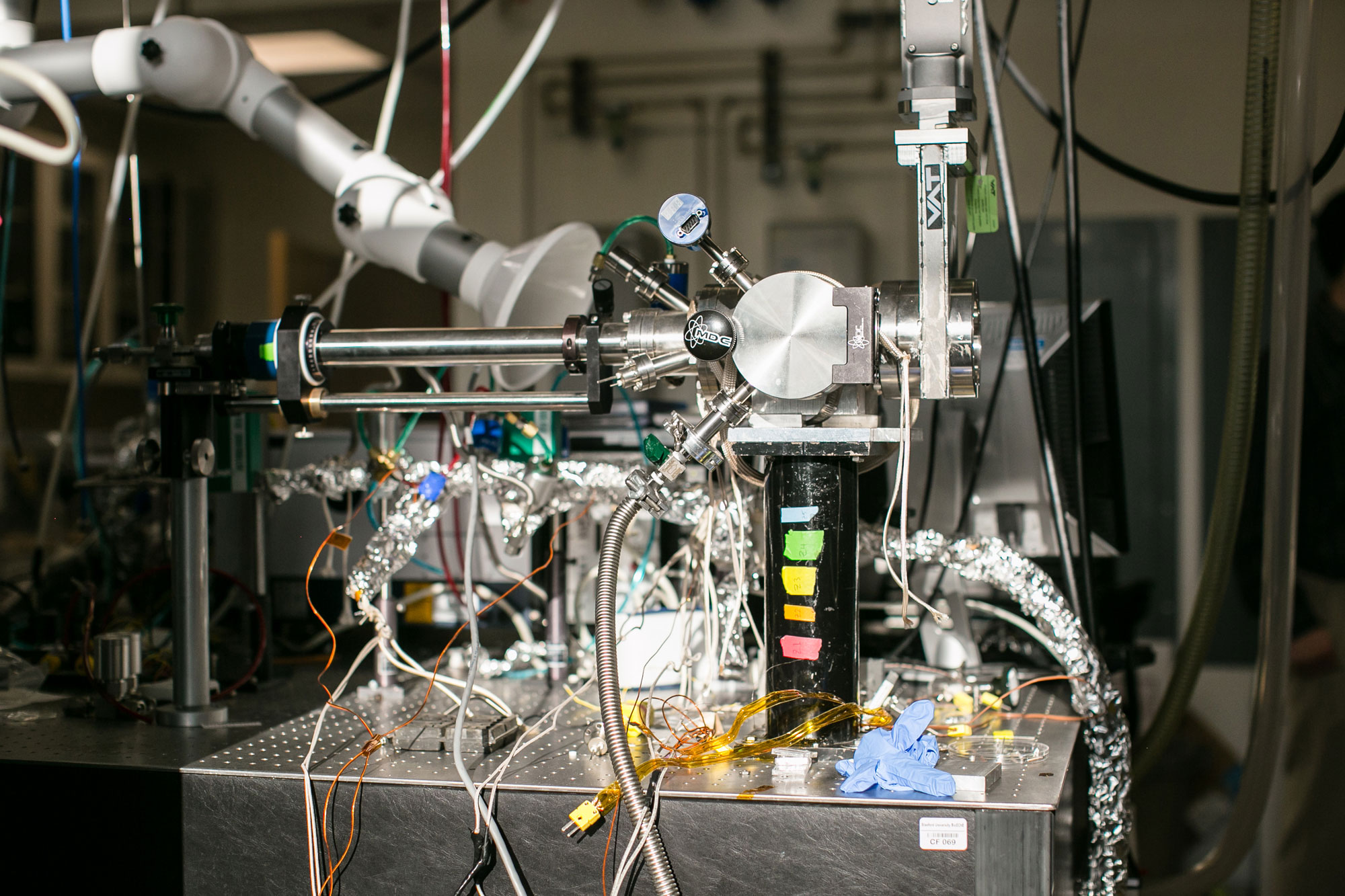

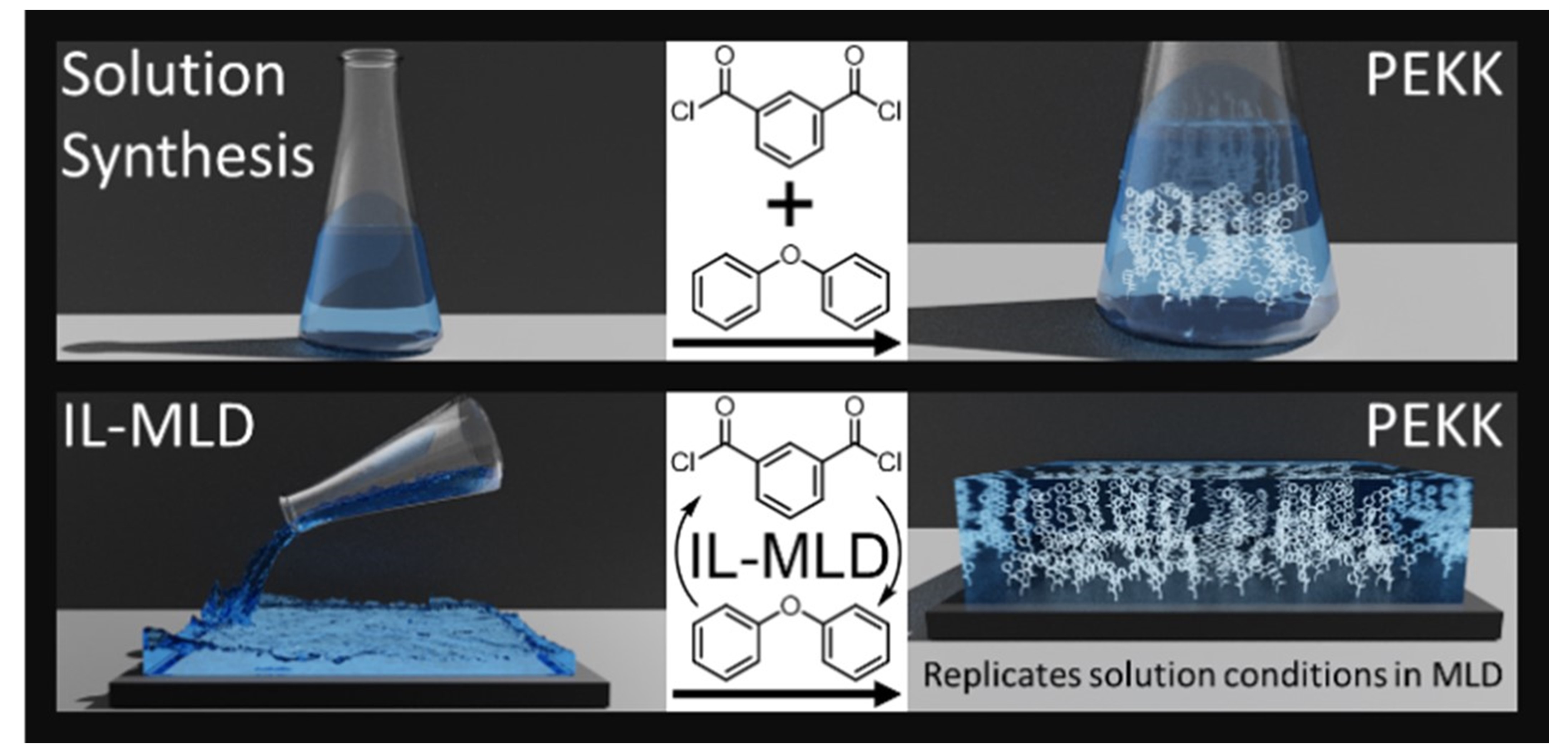

The ability to deposit nanoscale organic-based films with molecular level control is of importance for a range of applications for which precision in composition and architecture is crucial, such as nanoelectronics and catalysis. We are exploring the technique of molecular layer deposition (MLD) to deposit ultra-thin organic thin films. The molecular analogue to atomic layer deposition (ALD), MLD reactants that undergo self-saturating reactions are introduced in sequential schemes to grow films in a layer-by-layer manner. In these reactions, MLD utilizes multifunctional organic molecules to build oligomer films. Use of MLD for growth of organic films has many advantages over traditional chemical vapor deposition methods: precise control over film thickness, conformal coating of surfaces, and an unprecedented control over the film composition. In MLD, the organic backbone of each monomer can be changed to meet the needs of the desired applications, such as a desired surface functionality. Our group is currently studying various techniques to extend the chemistries able to be deposited via MLD. This is achieved through the use of vacuum-compatible solvents, such as ionic liquids (IL), present during the deposition process, allowing the actual surface reaction chemistry to occur in the solvent. This invites the possibility of using solvent-mediated reaction mechanisms in MLD, rather than only being limited to vapor-phase reaction mechanisms.

Above: Visualization of solvent-assisted molecular layer deposition

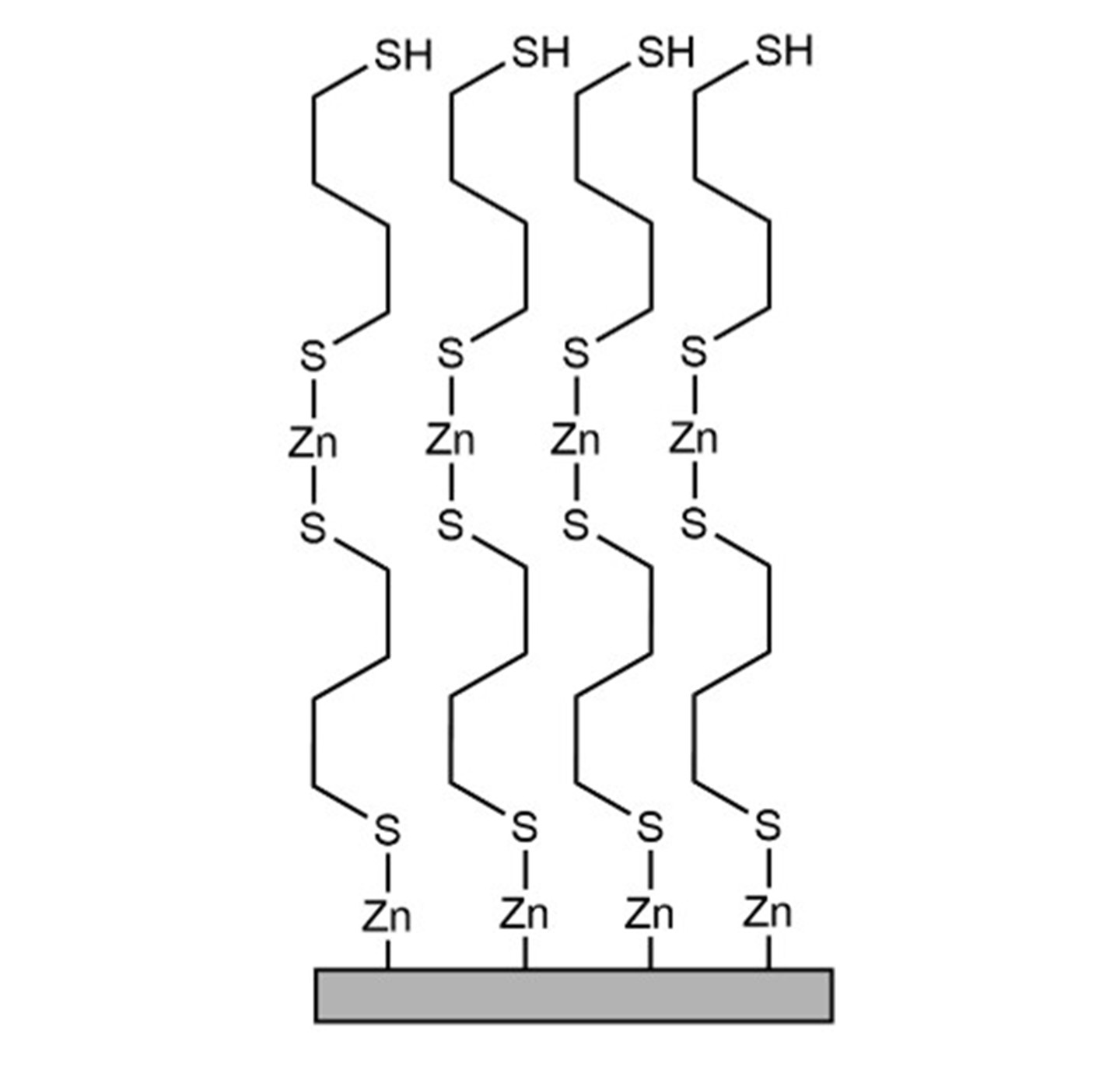

Hybrid materials or coordination polymers, in which metal atoms are repeatedly connected through bifunctional linker moieties, are also of great technological interest. Hybrid MLD, which combines metalorganic precursors used in ALD with organic precursors used in MLD, can deposit these hybrid materials at the nanoscale. Expanding upon the many studies of 'metalcones', where the organic linkers are alcohol-based, our lab is focusing on the potentially more robust metal thiolate class of materials, using thiols as the metal-coordinating functional group. Molybdenum thiolates have already been shown to have catalytic activity in the hydrogen evolution reaction, and we are exploring whether other hybrid analogues of catalytic materials, such as ZnS, may also offer interesting properties. These coordination polymers expand the domain of vapor-deposited thin films to allow for more flexible materials with applications in encapsulation, flexible electronics, and membranes. We are also currently working on several other applications of MLD/hybrid films: EUV photo and e-beam resists for next-generation lithography, flexible solid electrolyte layers (SEI) in lithium ion batteries, and flexible hydrogen evolution reaction (HER) catalysts.

Above: Ideal schematic of zinc thiolate film deposited via ALD/MLD.