Research Area: Lithium Batteries and Catalysis

Electrification of our energy and transportation sectors is essential for meeting the needs of global energy demand. Battery storage plays a key role in this transition by supporting the integration of renewable energy and facilitating the widespread adoption of electric transportation. To this end, it is critical to develop battery technologies that are higher-performing, more cost-effective, and environmentally sustainable.

Our research addresses these challenges by investigating the fundamental mechanisms underlying next-generation battery systems. Specifically, we focus on interface engineering to answer fundamental questions and solve pressing issues in next-generation lithium metal batteries by modifying surface layers and interfaces at the nanoscale, often using atomic layer deposition (ALD). Through this approach we aim to enhance the coulombic efficiency, cycle life, and capacity retention across various emerging battery technologies.

Above: Illustration of lithium electrodeposition on a substrate modified by a resistive ALD film. Here, few nucleation sites accompany the formation of lithium deposits with low packing density (low exposed surface area).

Oyakhire, Zhang, Cui, Bent, et al. Nature Communications 13, Article number: 3986 (2022). https://doi.org/10.1038/s41467-022-31688-7

Above: Planetary Lithium Islands. The cover image of the article by Shuchi, Cui, Bent, and co-workers depicts a unique planetary-like microstructure with lithium islands achieved by resistive hafnia coating on copper. The work introduces an interface engineering approach that allows the decoupling of two critical lithium (Li)-metal battery parameters-Li-morphology and solid electrolyte interphase (SEI)-in their kinetically convoluted regime. The article highlights that Li morphological control is more practical due to the challenges in SEI preservation.

Shuchi, Oyakhire, Cui, Bent, et al. Adv. Mater. Interfaces 2024, 11, 2400693. https://doi.org/10.1002/admi.202400693

There is an increasing demand for low-cost, efficient pathways to produce fuels and reduce the environmental impact of transportation, while also making better use of scarce and expensive precious metals. Catalysts are central to enabling these transformations, but their performance is often constrained by inherent tradeoffs between activity, selectivity, and stability, which can reduce overall metal utilization efficiency. Traditional synthesis techniques also make it challenging to isolate how specific catalyst properties influence stability and reactivity.

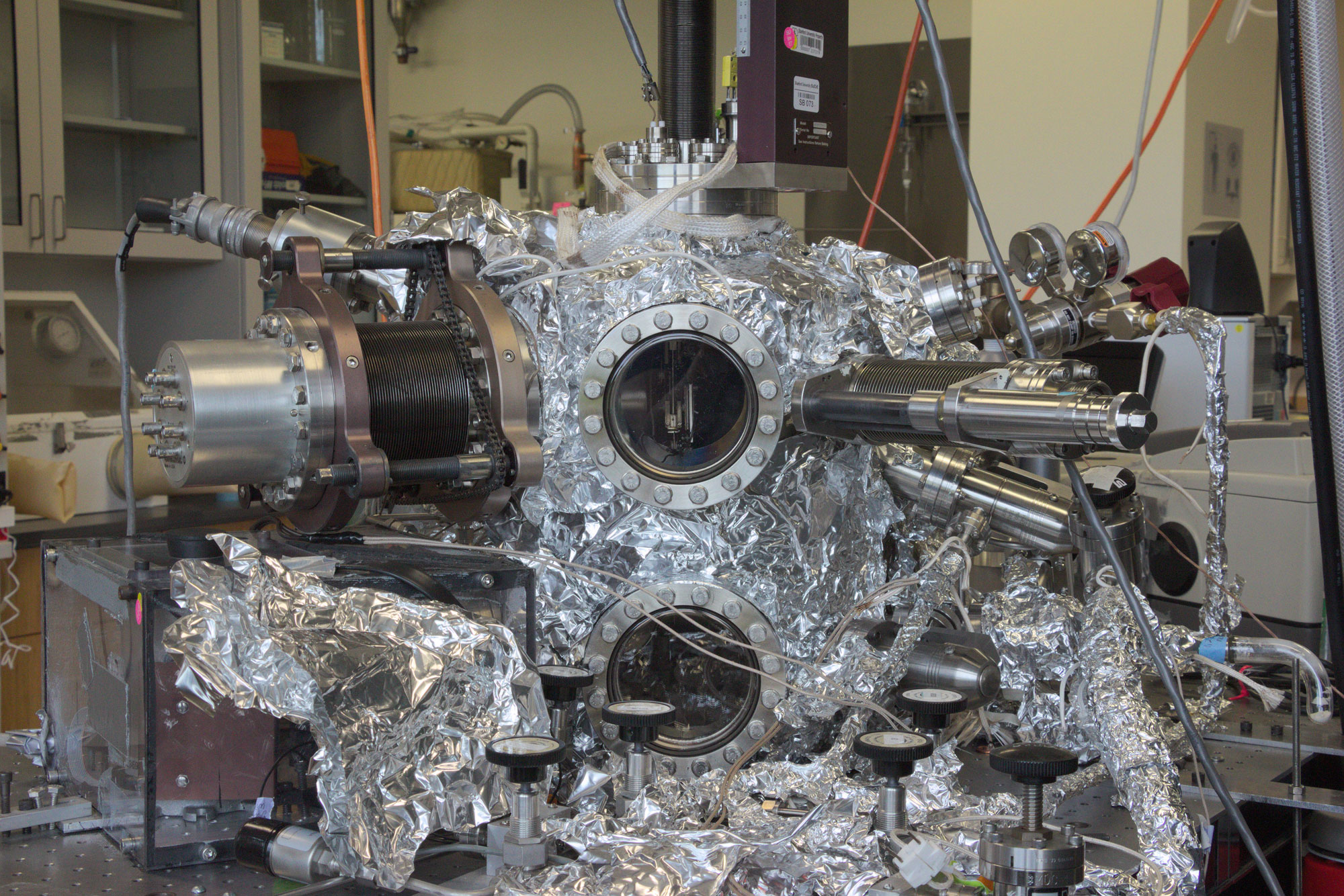

Our research addresses these challenges by developing new materials and strategies for both fuel production and emission control catalysis. We investigate CO2 and CO hydrogenation to alcohols as well as the stabilization of platinum group metals (PGMs), which are indispensable in emission control systems but suffer from high cost and limited supply. Using atomic layer deposition (ALD), we design oxide coatings, promoters, and alloy architectures to control catalyst structure, tune surface chemistry, and suppress certain deactivation mechanisms. By combining ex-situ characterization with in-situ synchrotron techniques, we develop fundamental insights into catalyst structure-property relationships, reaction chemistries, and deactivation pathways. Together, these efforts advance a mechanistic understanding of how ALD can be leveraged to design durable, efficient catalysts for cleaner energy and environmental technologies.

Above: TEM micrograph of a sub-nm alumina ALD coating a rhodium supported on zirconia emission control catalyst.